Tag: Lee Ann Carter

Southwinds Magazine Dania Marine Flea Market

Charleston City Paper-A Fear Greater than Pain

She was only 16 the night she walked into the kitchen and discovered her mother passed on the floor. It wasn’t an accident or stroke, it was a drug overdose. While it sounds like the first paragraph of a bad novel or something you might see on Jerry Springer, it happened to me 30 years ago. My mother, a registered nurse, knew all the right words to say to her doctors so they would prescribe the drugs she craved. That night, as I ran screaming across the front yard to wake the next door neighbor because I thought she was dead, I swore that monkey would never be allowed to make a home on my back.

Fast forward to today and let’s sneak a peek into my medicine cabinet. Tums for the calcium, assorted lotions and creams, several sample sized bottles of cosmetics, hmmm, what’s missing? NO DRUGS! No aspirin, no Tylenol, no small round bottles from the local pharmacy bearing unpronounceable names.

Drugs eventually played a part in my mother’s death and because of that I live with the very real fear of drug addiction; but I am by no means stupid or reckless with my health. I get an infection; I call my doctor, take the prescribed course of antibiotics, and feel better. What I don’t take is any pain medication, over the counter or prescribed.

So you ask, “What about headaches or the occasional ache or pain?” Headaches are only something I hear my husband complain about or discussed in TV commercials. I can count on one hand the number of headaches I’ve had in my entire life. For the rare backache or muscle pull I treat myself with hot/cold compresses and mind relaxation therapy; I am a very firm believer in the mind/body connection.

Because drug addiction, especially addiction to prescription medications, is so prevalent in today’s society, I’m sure my fear, while manifested under different circumstances, is felt by a large majority of the population. Many health care professionals are reluctant to prescribe needed pain medications because they fear their patients will become addicted. While for those who do, in many cases, their patients refuse to take the recommended dosage needed because of that same fear.

Today with alternative medicine becoming mainstream there are more options for controlling pain than just popping a pill or being injected with a strong narcotic. These doctors are trained to help their patients control pain through a variety of methods. They discuss addiction with their patients, educate them on the difference of addiction vs physical dependence, and then if they are still adamant about no drugs, explore different methods of coping with their pain such as bio-feedback, acupuncture and acupressure, herbal remedies,massage therapy, and lifestyle changes.

Cutting-edge pharmaceutical manufacturers have created many new and exciting potions considered by some to be “miracle drugs.” The narcotic Oxy-Contin offers an increasing analgesic effect in increased doses. In plain English that means the more you take, the better your feel. While people with unrelenting pain have had phenomenal relief with Oxy-Contin the danger on unintentional addiction is a real concern. Purdue Pharma, Oxy-Contin’s manufacturer, has begun warning physicians to be alert for signs of dependence in their patients. For street addicts bypassing the controlled release mechanism by chewing, snorting, or injecting Oxy-Contin, they experience an instant and intense high much like that of injecting high-grade heroin.

Oxy-Contin addiction has been featured on several news programs recently. In checking with law enforcement agencies from Folly Beach to North Charleston, all agree that Oxy-Contin, at the present time, is not a problem here. But all were quick to say that since it is such an epidemic in other parts of the United States, it’s only a matter of time before it reaches the Lowcountry.

Is a fear of drug addiction a legitimate concern to someone with chronic pain due to an accident, disease, or illness? Certainly it seems that way with Oxy-Contin. Is dependence any stronger with Oxy-Contin that it was when Dilaudid was the drug of choice several years ago or is it just the newest kid on the block soon to be replaced by something stronger and even more addictive?

These are concerns that need to be addressed with your physician before that prescription, whether for Oxy-Contin or any other pain reliever, is written. Openly discuss your fears, and, if your apprehensions are not taken seriously, then certainly consider choosing another health care professional.

It is your life, and your health, both mental and physical, and it only makes sense that you be an active participant.

Port Charleston Magazine Quoizel Lighting & Home Furnishings Illuminating Success

In 1994 when Quoizel Lighting and Home Furnishings was rapidly outgrowing its New York/New Jersey facilities, the only additional land available for expansion near their Long Island plant was five acres, on the market for more than $1 million. While neither New York officials nor the local utilities made much of an effort to retain Quoizel’s business, economic developers in both South Carolina and Georgia welcomed Ira Phillips, Quoizel’s CEO and owner, with open arms.

In 1994 when Quoizel Lighting and Home Furnishings was rapidly outgrowing its New York/New Jersey facilities, the only additional land available for expansion near their Long Island plant was five acres, on the market for more than $1 million. While neither New York officials nor the local utilities made much of an effort to retain Quoizel’s business, economic developers in both South Carolina and Georgia welcomed Ira Phillips, Quoizel’s CEO and owner, with open arms.

Goose Creek won out over Savannah, and Phillips took the offer of 63 acres for $900,000-roughly $15,000 an acre. Incentives offered by the state and Berkeley County included 15-year state and local tax abatements and free training for workers hired who had been on welfare or displaced from other jobs. The area was then designated a foreign trade zone by the South Carolina Department of Commerce, which enabled Quoizel to import parts from overseas duty free.

The perks didn’t end there. Not only were utility rates a third of those in Long Island, but the cost of transporting a shipping container from port to warehouse was $50, compared to $350 in New York.

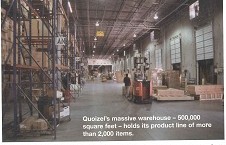

Construction started in 1995 on the 300,000 square foot, $10 million state-of-the-art facility. In 1999 an additional 200,000 square feet was completed.

Quoizel made national headlines in 1996 when they relocated not only upper management and supervisors but also nearly 75% of the factory workers as well.

While the move cost Quoizel more than 41 million, the novel approach seemed to have worked. Whereas statistics show that most factories struggle during the first year of a major relocation, Quoizel ended 1996 with a 20% increase in revenue. By transferring experienced production employees and going the extra mile to help them relocate, Quoizel benefited in several ways. By transferring experienced workers, new line employees were able to receive hands-on training, so downtime before inventory could be shipped was minimal. Along with lump sums paid for moving costs, Quoizel negotiated special deals with movers and even gave employees new washers and dryers. The company’s generosity also helped boost employee loyalty.

With a straightforward operating philosophy-“deliver value and apply that principle to every phase of the business”-Quoizel offers a full product line of more than 2,000 items, including wall fixtures, table and floor lamps, as well as one of the industry’s largest selections of Tiffany-styled pieces. The company’s designers stay on the cutting edge of trends in residential architecture and interior design. In 1998 Quoizel introduced it’s furniture line and last year debuted Lenox Lighting, a lighting collection in conjunction with Lenox China.

Quoizel has more than 2,000 retail distributors, the majority located within the United States. Approximately 10% of Quoizel’s annual sales are foreign generated, primarily from Canada and South America. International business consists mainly of importing finished goods from Asia, The Philippines, Mexico, Canada, Spain, France and Italy. Approximately 80% of everything shipped into the Goose Creek facility is foreign-made, with China the main producer of almost 90% of all Quoizel imports.

Because transportation plays a major role in Quoizel’s success, Operations Manager Ed Clark applauds both Atlantic Trucking Company and Evergreen America Shipping. “Both companies are very ‘user-friendly’ and run like clockwork,” Clark says. “Quoizel uses the Port of Charleston exclusively because of one work: Location. Their proximity to our plant makes scheduling of shipments a one-step process, and Atlantic Trucking is able to give us a turn-around time of 20-30 minutes, which also simplifies the operation. My hat is off not only to the Ports Authority but to Evergreen and Atlantic as well.”

With revenues exceeding $82 million in 2000, Quoizel has proven that combining a quality-based management philosophy with cutting-edge technology and the ability to track current market cycles can produce illuminated success.

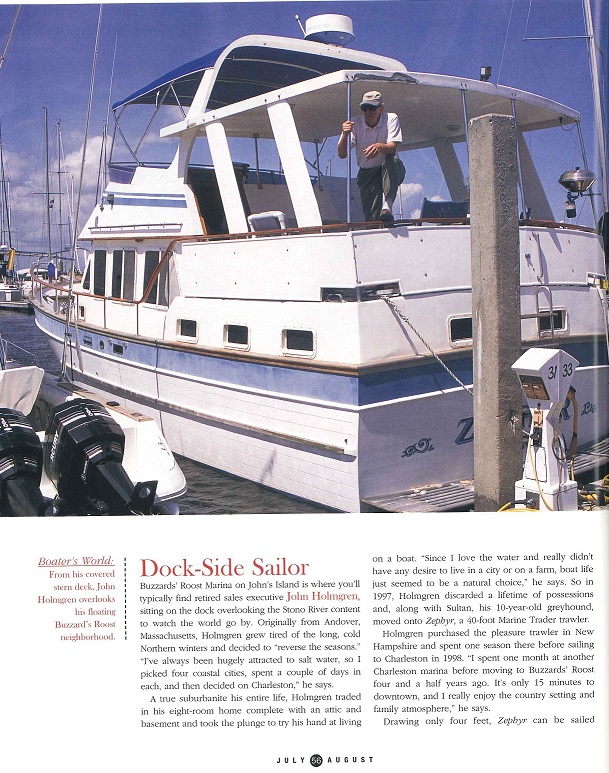

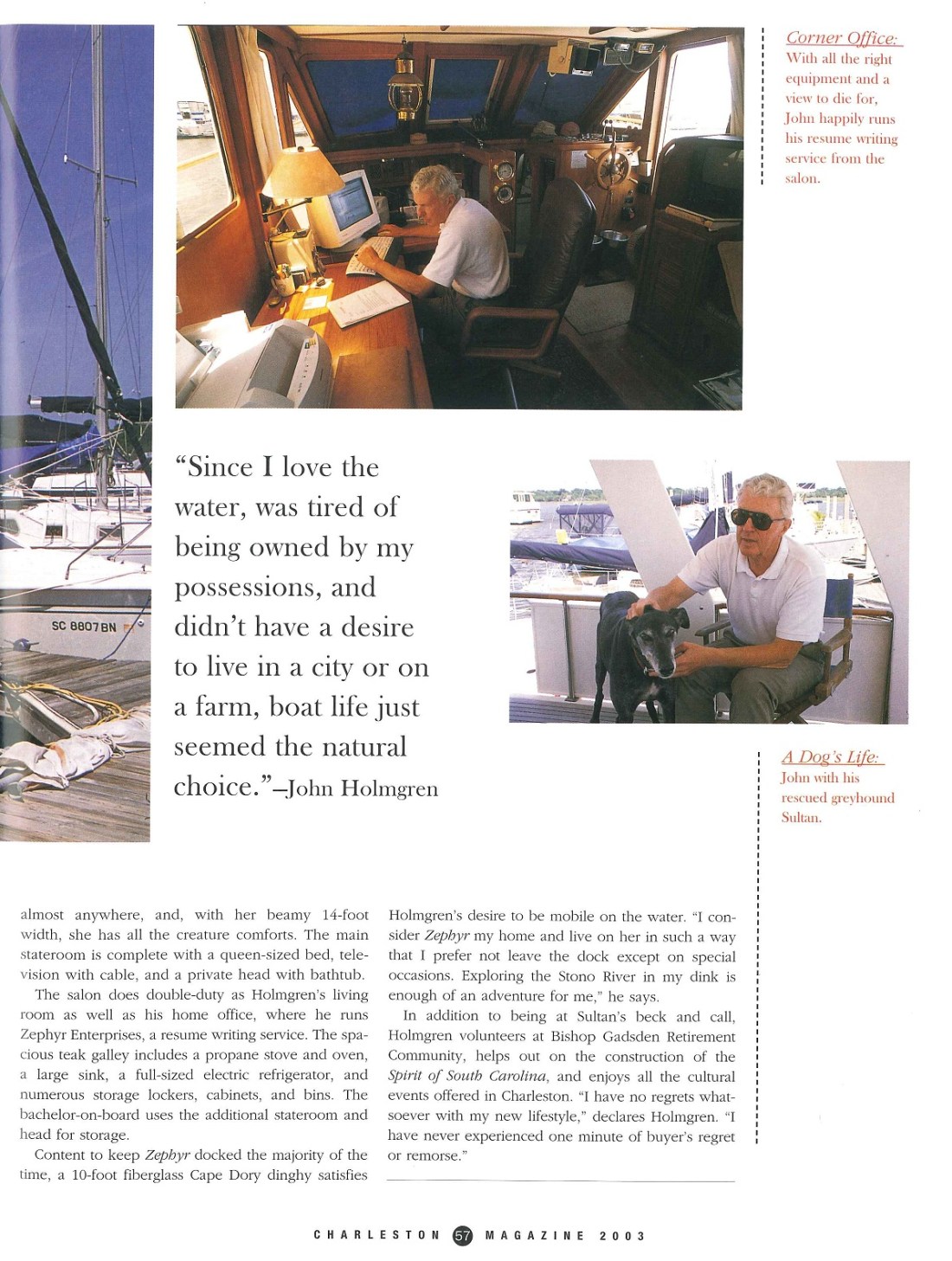

Living Aboard Magazine Nine to Five

Published March/April 2003 issue

Work: it’s a fact of life. Since graduating from college I have always been employed by someone else – then, a couple of years ago, I was “downsized” due to the economy. After getting over the initial shock, I took losing my job as a sign to finally fulfill my dream of becoming a freelance writer.

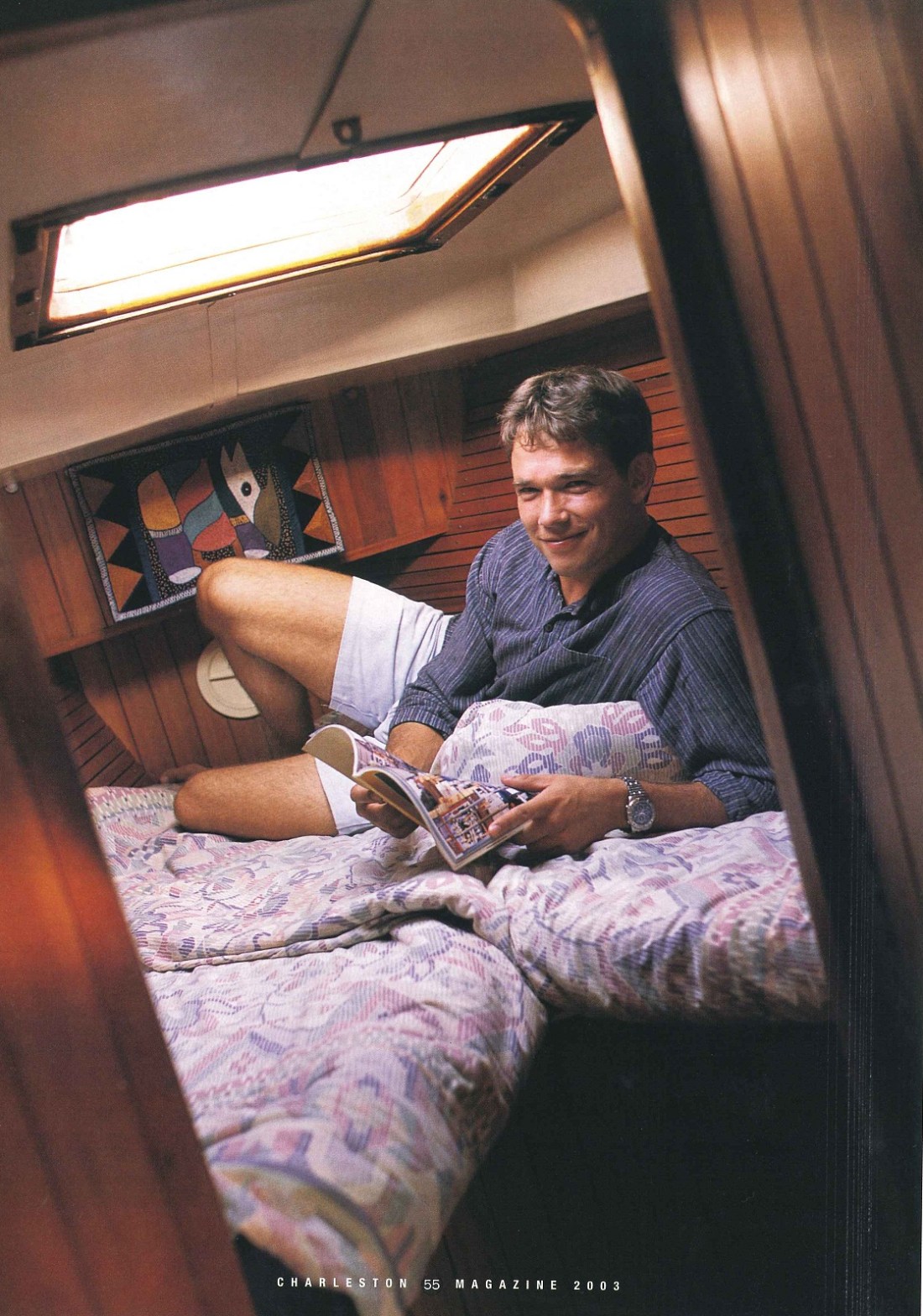

It was also during this time that my husband, Marc and I decided to sell our home, buy a boat, a 36′ Bayfield sailboat named Nisus, and become, along with our four cats and two dogs, full-time liveaboards. Being self employed helped tremendously with the transition from land-based home to boat. As a writer my schedule was flexible enough that if we had a boat emergency I could handle it without having to explain bilges or pumps or 12-volt electrical systems to a landlubber boss.

While I wasn’t making the kind of money I had in the past by reducing living expenses we were doing OK. Until Marc, lured by tales of sailing the seven seas, came home one day to announce that he was tired of sailing the Charleston Harbor and surrounding lntracoastal Waterways and wanted to get started on our plan of sailing to Cadiz, Spain where we had friends. While that was our original plan I had become content living at the dock with all those modern conveniences shore power provides. Plus, leaving Charleston would mean that while I would still be self-employed (a writer can write anywhere), Marc would be unemployed, putting a crimp in our lifestyle. After much discussion I agreed to go back to work full-time for someone else in order to finance our voyage.

Now came the hard part – not actually finding a job-that was a snap – but the logistics of returning to a set schedule and looking presentable while doing so.

While Nisus has an almost full-sized bathtub I still use the marina shower every couple of days to wash my hair. A six-gallon hot-water heater and hand-held shower nozzle just doesn’t work well on thick, shoulder-length curly hair. Our marina has very limited facilities, and while there aren’t many liveaboards, one shower still isn’t enough when you have a couple of people trying to get to work at the same time. In the past it wasn’t a problem since I set my own hours. But now I had to be on time and professionally dressed, since I come into contact with other employees as well as the general public. I finally learned everyone’s schedule, and as long as everyone sticks to their routine things are fine. God forbid if we get a transient docked at the marina for a couple of days, especially an early riser!

When I lost my job and then moved onto the boat I donated the majority of my professional wardrobe to a local organization that helps dress low-income women transitioning from welfare to the workplace. Being self employed, my normal office attire was shorts and t-shirts when it was hot and jeans and sweatshirts when it was cold. Now I had not only to purchase a working wardrobe, I also had to find some place on the boat to store it and a way of maintaining it.

Nisus has two hanging lockers, one in each stateroom. The locker in the aft stateroom was built to fit from the underside of the side deck to the floor, but when we had a Cruise-Air heating and cooling system installed, the duct-work into the main salon was run throught the bottom of that locker. Now the inside height is approximately the same as the one in our stateroom, which was built from the underside of the top deck down to a nice and convenient built-in bench. Great for sitting down to tie your sneakers, but it doesn’t do much in the way of keeping dresses from becoming wrinkled.

And speaking of shoes, where does one keep shoes on a boat? When not on my feet, my boat shoes are in plain view in the stateroom, while the rest are stored under one of the salon seats. Since the majority are leather, they have to be checked periodically for mold and mildew, cleaned, and then repacked. Plus, you haven’t really lived until there you are, all dressed up, hair and make-up perfect, clothes neatly pressed, crouched down on all fours with two dogs and four cats wanting to help while you search in a space 8 inches high for a shoe to match the one in your hand.

And speaking of shoes, where does one keep shoes on a boat? When not on my feet, my boat shoes are in plain view in the stateroom, while the rest are stored under one of the salon seats. Since the majority are leather, they have to be checked periodically for mold and mildew, cleaned, and then repacked. Plus, you haven’t really lived until there you are, all dressed up, hair and make-up perfect, clothes neatly pressed, crouched down on all fours with two dogs and four cats wanting to help while you search in a space 8 inches high for a shoe to match the one in your hand.

I finally purchased several pairs of lightweight knit pants with matching tops and a couple of dresses in a rayon-poly blend. All are easy to care for, machine washable and basically wrinkle-free; though l did invest in a small compact iron for those quick touch-ups. The hanging locker in our stateroom is spacious (wide) enough to accommodate my new wardrobe. After hanging the dresses, using clothes pins, I take the hems and pin them even with the shoulders to minimize wrinkling.

Then there was the lighting issue. Nisus has two lights in the head – one over the bathtub, and one next to the sink. Unfortunately, even with both turned on they don’t provide the necessary light needed for things like applying eye makeup or shaping eyebrows.

One day at Wal-Mart I discovered a small round lighted make-up mirror that can run off either batteries or shore power. It’s compact size is perfect for the boat, plus the wattage provides more than enough light needed for applying mascara or blush.

Six weeks passed and things had been going pretty well when I had to face what I had been dreading. I woke to the sound of rain. Not just a drizzle, a pounding, gully-washing downpour! Thank goodness it wasn’t hair washing day, but I still had problems since it’s a 1,200-foot walk down an uncovered dock to my car. I lay there in my nice, warm, dry berth weighing my options; (a) I could call in sick. No, hadn’t been on the job long enough for that. (b) I could just go in late. See a. (c) I could quit. No, then I would have to face the husband. (d) I could get up, get dressed, and make a run for it. Being responsible, I chose d. Even with foul- weather gear, I was still pretty damp by the time I reached my car. But worse was yet to come: it rained the following 10 days in a row. By about day five I was beginning to believe going to work looking half drown was normal!

So far I have dwelled on the practical aspects of working full time and living on a boat. While sometimes the logistics have been difficult, the hardest transition for me has been the loss of personal time and the freedom to set my own schedule. I used to think nothing of starting my daily writing before the sun rose in order to have the afternoon off for a leisurely sail. Or, if I didn’t have time to make my weekly trip to the Laundromat, no problem, I would just dig out another t-shirt. That’s no longer an option. I have also lost that special time sitting in the cockpit with a steaming cup of coffee watching the sun rise.

I know it will all be worth it in the long run. The closer we get to our goal of a long voyage, the more excited Marc becomes, and his exuberance is contagious. I am beginning to look forward to casting off the bowlines and sailing into the sunset, if for no other reason than I will again be my own boss and waking to the pitter-patter of raindrops will be nothing more than an invitation to roll over and go back to sleep – unless, of course, it’s my turn on watch.

Lee Ann Carter has recently been published in South Carolina Homes and Gardens, Southwinds Sailing, Charleston Home Design and The Charleston City Paper.

South Carolina Homes & Gardens Martin Gallery

South Carolina Homes & Gardens Carolina Girls

South Carolina Home & Gardens Palmetto Moon Antiques

Charleston Magazine An Officer and a Gentleman

published in the June, 2004 issue

Shortly after the Charleston, SC Navy Base closed in 1996, the U.S. Border Patrol moved their training facility onto the southern end of the base. I was invited to spend the day with P.T Instructor Paul Thauer to experience for myself the rigorous daily physical schedule the new cadets were subjected to.

Click to Enlarge